Blog

Ultimate Guide to DTF Printing Machines in Kenya 2026

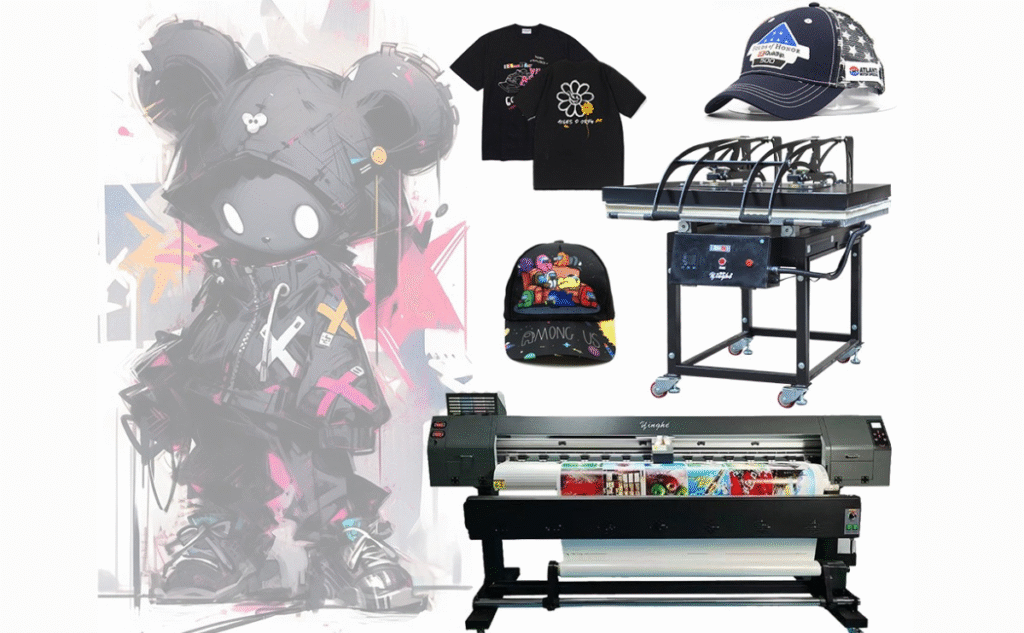

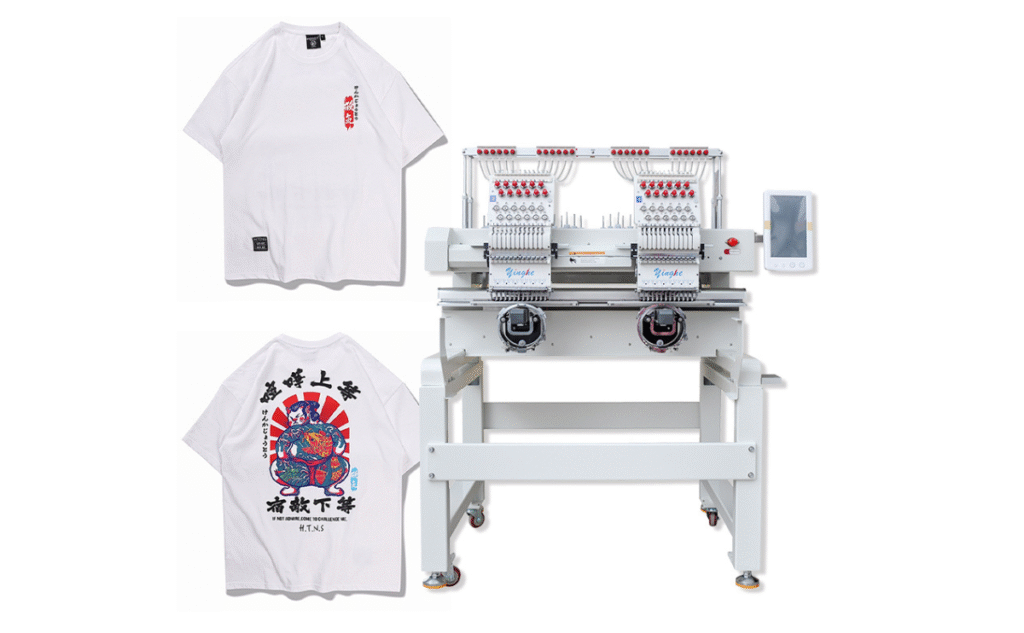

DTF printing machines are revolutionizing custom apparel and branding in Nairobi's bustling market. These versatile Direct-to-Film printers offer vibrant, durable prints on any fabric without pre-treatment, making them ideal for Kenyan businesses scaling up T-shirt sales and promotional gear.

What is DTF Printing?

Direct-to-Film (DTF) printing prints designs directly onto a clear PET film using water-based inks, including a white layer for opacity. Hot-melt adhesive powder bonds to the wet ink, gets cured in an oven, and transfers via heat press to cotton, polyester, leather, or even wood. Unlike DTG, no pretreatment is needed, slashing setup time for small runs.

This process shines for East African printers targeting e-commerce sellers who need quick, colorful custom orders. Machines range from compact A4 units for startups to industrial 60cm models handling bulk production.

How DTF Printing Machines Work

DTF setups include three core components: printer, powder shaker, and curing oven.

Printing: Mirror your design in RIP software; print CMYK colors first, then white ink on an Epson or Brother inkjet modified for pigment inks.

Powder Application: Shake on TPU adhesive powder evenly—the tacky ink grabs it perfectly.

Curing: Bake at 150-160°C for 2-3 minutes to form a flexible film layer.

Transfer: Hot press at 160°C for 12-15 seconds, peel warm, and done—machine-washable up to 60 cycles.

Top Benefits for Kenyan Businesses

DTF excels in Kenya's diverse fabric market, from kitenge blends to sportswear polyesters.

Vibrant colors pop on dark fabrics thanks to white underbase—no fading like sublimation.

Soft-hand feel rivals screen printing but with unlimited colors and photorealistic details.

Low startup costs: A full A3 setup runs KSh 500K-1.5M, with ROI in 3-6 months via 500 shirts/month.

Eco-friendly pigments; no vinyl weeds or water waste.

Setting Up Your DTF Printing Business in Nairobi

Space: 10x10ft ventilated room with power backup—key in Kenya's grid.

Supplies: Buy CMYKW inks (1L KSh 4K each), film ( KSh 4500), powder(2K) from Morjay.

Software: AcroRIP or CADlink for color management.

Marketing: Target Facebook/Instagram ads to uniform makers, event planners. Use SEO captions like "DTF printer Nairobi price."

Training: 2-day hands-on at Morjay Graphics—master peeling tricks for flawless edges.

Expect 200-300 prints/day on entry-level machines.

Maintenance and Troubleshooting Tips

Clean printheads weekly with solution to avoid clogs.

Store powder in cool, dry spot—humidity kills adhesion.

Test wash fastness: Print samples, launder 10x.

Common fix: Bubbly transfers? Reduce press time by 2s.

Related Posts

Top Trending Printing and Branding Machines in 2026

PRINT ON DEMAND BUSINESS IN 2026: SELLING CUSTOMIZED MERCHANDISE

Starting a DTF Printing Business in Kenya: Your Comprehensive Guide to Startup Costs and Profitability

Direct-to-Film (DTF) printing has rapidly emerged as a game-changer in the Kenyan branding and apparel customization industry.