Blog

Starting a DTF Printing Business in Kenya: Your Comprehensive Guide to Startup Costs and Profitability

Introduction

Direct-to-Film (DTF) printing has rapidly emerged as a game-changer in the Kenyan branding and apparel customization industry. Offering vibrant, durable, and versatile prints on a wide range of fabrics, DTF technology presents an exciting opportunity for entrepreneurs looking to enter or expand their printing businesses. If you're considering starting a DTF printing business in Kenya, understanding the initial startup costs is crucial for effective planning and sustainable growth. This guide will break down the essential expenses, from equipment to consumables, and provide insights into potential profitability.

Why Invest in DTF Printing in Kenya?

DTF printing offers several compelling advantages that make it an attractive venture in the Kenyan market:

•Versatility: Prints on almost any fabric type, including cotton, polyester, blends, nylon, and leather, without pre-treatment.

•Vibrancy & Durability: Produces high-quality, full-color prints that are soft to the touch, stretchable, and highly resistant to washing and cracking.

•Efficiency: Streamlined process compared to traditional methods like screen printing, allowing for faster turnaround times.

•Lower Entry Barrier: While requiring an initial investment, DTF can be more accessible than some other advanced printing technologies, especially with entry-level machines.

•Growing Demand: The demand for custom apparel, promotional items, and personalized branding is consistently rising in Kenya, creating a fertile market for DTF services.

Key Startup Cost Categories for a DTF Business

1. DTF Printing Equipment

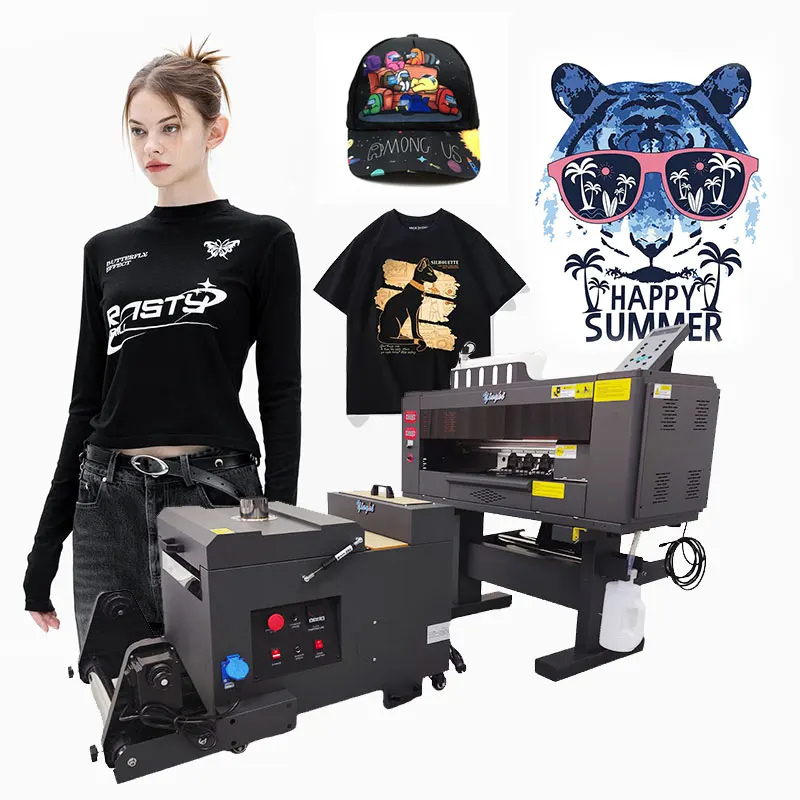

The core of your business will be the DTF printer itself, along with supporting machinery. The cost can vary significantly based on the machine's size, speed, printhead configuration (e.g., Epson XP600, i3200), and brand.

•DTF Printer: Entry-level desktop DTF printers (A3/A4 size) can range from KShs 150,000 to KShs 400,000. Larger, more professional roll-to-roll DTF printers (60cm or 1.8m width) with dual printheads offer higher output and advanced features, costing anywhere from KShs 500,000 to KShs 1,500,000 or more . Morjay Graphics offers a range of these machines, including the popular 60 cm DTF Printing Machine with Dual Epson I3200 Print Heads.

•Powder Shaker & Curing Oven: After printing, the wet ink needs to be coated with adhesive powder and then cured. Some DTF printers come with integrated shaker and curing units, while others require separate units. A standalone curing oven might cost KShs 30,000 to KShs 100,000. Integrated systems will be part of the printer's overall cost.

•Heat Press Machine: Essential for transferring the cured DTF film onto garments. A good quality heat press (e.g., 15x15 inch or 16x20 inch) is a must-have. Prices for these can range from KShs 40,000 to KShs 150,000, depending on size and features (manual, semi-automatic, pneumatic) . Morjay Graphics offers various heat press machines, including multifunctional 10-in-1 and 15-in-1 options.

•Computer & Design Software: A reliable computer with sufficient processing power and RAM is needed to run design software (e.g., Adobe Photoshop, Illustrator, CorelDRAW) and RIP (Raster Image Processor) software, which is crucial for DTF printing. Software licenses can be a recurring cost or a one-time purchase.

2. Consumables

These are the ongoing expenses that directly impact your production costs.

•DTF Film: The special film onto which the design is printed. Available in rolls or sheets, costs vary by size and quality. Expect to spend KShs 5,000 to KShs 20,000 per roll depending on width and length.

•DTF Inks: Specialized CMYK and white inks are required. White ink is particularly important for DTF and is often consumed faster. A set of high-quality DTF inks can cost KShs 10,000 to KShs 30,000 or more, depending on bottle size and brand.

•DTF Adhesive Powder: The thermoplastic adhesive powder that binds the ink to the fabric. Prices range from KShs 2,000 to KShs 8,000 per kilogram.

•Garments/Substrates: The cost of t-shirts, hoodies, caps, or other items you will be printing on. Sourcing these in bulk from local suppliers can help reduce costs.

3. Other Essential Costs

Don't overlook these additional expenses that contribute to a fully functional business.

•Workspace: Rent for a small workshop or office space, or setting up a dedicated area in your home. Consider factors like ventilation and power supply.

•Utilities: Electricity consumption for machines, internet for orders and design work.

•Marketing & Branding: Website development, social media marketing, business cards, and samples to showcase your work. This can range from KShs 10,000 to KShs 50,000+ initially.

•Training: While Morjay Graphics offers free training with machine purchases, additional advanced design or business management courses might be beneficial.

•Miscellaneous: Packaging materials, spare parts, and emergency funds.

Estimated Startup Cost Summary (Kenya Shillings)

Here's an estimated breakdown for different scales of a DTF printing business:

Item | Entry-Level (Home-based/Small Scale) | Medium-Scale (Small Workshop) |

DTF Printer | KShs 150,000 - 400,000 | KShs 500,000 - 1,500,000 |

Powder Shaker/Curing | KShs 30,000 - 100,000 (if separate) | Included with printer or KShs 80,000 - 200,000 |

Heat Press Machine | KShs 40,000 - 80,000 | KShs 80,000 - 150,000 |

Computer & Software | KShs 50,000 - 100,000 | KShs 80,000 - 150,000 |

Initial Consumables | KShs 20,000 - 50,000 | KShs 50,000 - 150,000 |

Workspace Setup | KShs 10,000 - 30,000 | KShs 50,000 - 200,000 |

Marketing & Misc. | KShs 10,000 - 30,000 | KShs 30,000 - 100,000 |

Total Estimated Startup | KShs 310,000 - 790,000 | KShs 870,000 - 2,450,000+ |

Note: These are estimates and actual costs may vary based on supplier, brand, and specific business needs.

The profitability of a DTF printing business in Kenya can be substantial, given the high demand for custom products. Your ROI will depend on several factors:

•Pricing Strategy: Research local market rates for custom apparel and branding services. Consider your cost per print, overheads, and desired profit margin.

•Volume of Orders: The more orders you process, the faster you'll recoup your initial investment. Marketing and networking are key.

•Efficiency: Optimizing your workflow, minimizing material waste, and maintaining your machines (as highlighted in our Essential Maintenance Tips for Your DTF Printer) will improve profitability.

•Value-Added Services: Offer design services, bulk discounts, or specialized products to attract more clients.

Many entrepreneurs in Kenya have found success with DTF, often achieving a return on investment within 6-12 months, especially with a consistent client base

Tips for Success in Your DTF Venture

1.Start Small, Scale Up: Begin with an entry-level setup to test the market and build your client base before investing in larger, more expensive equipment.

2.Quality is Key: Always prioritize high-quality prints and durable products to build a strong reputation.

3.Continuous Learning: Stay updated on the latest DTF techniques, software, and market trends.

4.Network: Connect with local businesses, event organizers, and designers who might need your services.

5.Partner with a Reliable Supplier: Choose a supplier like Morjay Graphics that not only provides quality machines but also offers comprehensive after-sales support, spare parts, and training.

Conclusion

Starting a DTF printing business in Kenya is a viable and potentially highly profitable venture. While the initial investment requires careful planning, the versatility and growing demand for custom prints make it an exciting opportunity. By understanding the startup costs, focusing on quality, and leveraging reliable equipment and support from partners like Morjay Graphics, you can set your DTF business on the path to success.

Ready to take the next step? Explore Morjay Graphics' range of DTF printers, heat presses, and consumables today to kickstart your printing journey!

Related Posts

Ultimate Guide to DTF Printing Machines in Kenya 2026

Discover top DTF printing machines in Kenya for vibrant, durable custom prints on any fabric.

Top Trending Printing and Branding Machines in 2026

The printing and branding industry continues to evolve at a rapid pace, driven by technological inno...

PRINT ON DEMAND BUSINESS IN 2026: SELLING CUSTOMIZED MERCHANDISE

Direct to Film (DTF) printing has rapidly gained momentum in the printing industry in 2026. Offering...